1-Port Enhanced Calibration

Application

- S-Parameters Measurements (Only S11, S21)

- 1-Tone Measurements (Pin, Pout, Gt, Gp, PAE, AMPM, Harmonics Power, A1, B1, B2 …)

- 2-Tones Measurements(Pin, Pout, Gt, Gp, PAE, AMPM, C/In, OIPn …)

- Video Bandwidth (VBW) Measurements

- Modulation Measurements (Pin, Pout , Gt, Gp, PAE, AMPM, Harmonics Power, A1, B1, A2, B2, GammaLoad, ACPR, ...)

- Reflection Standards (OPEN, SHORT, LOAD) are connected to the source port to be calibrated

- THRU standard is connected between the two ports

- Power Sensor Standard is connected to the source port to calibrate the absolute power

Setup Editor Requirement

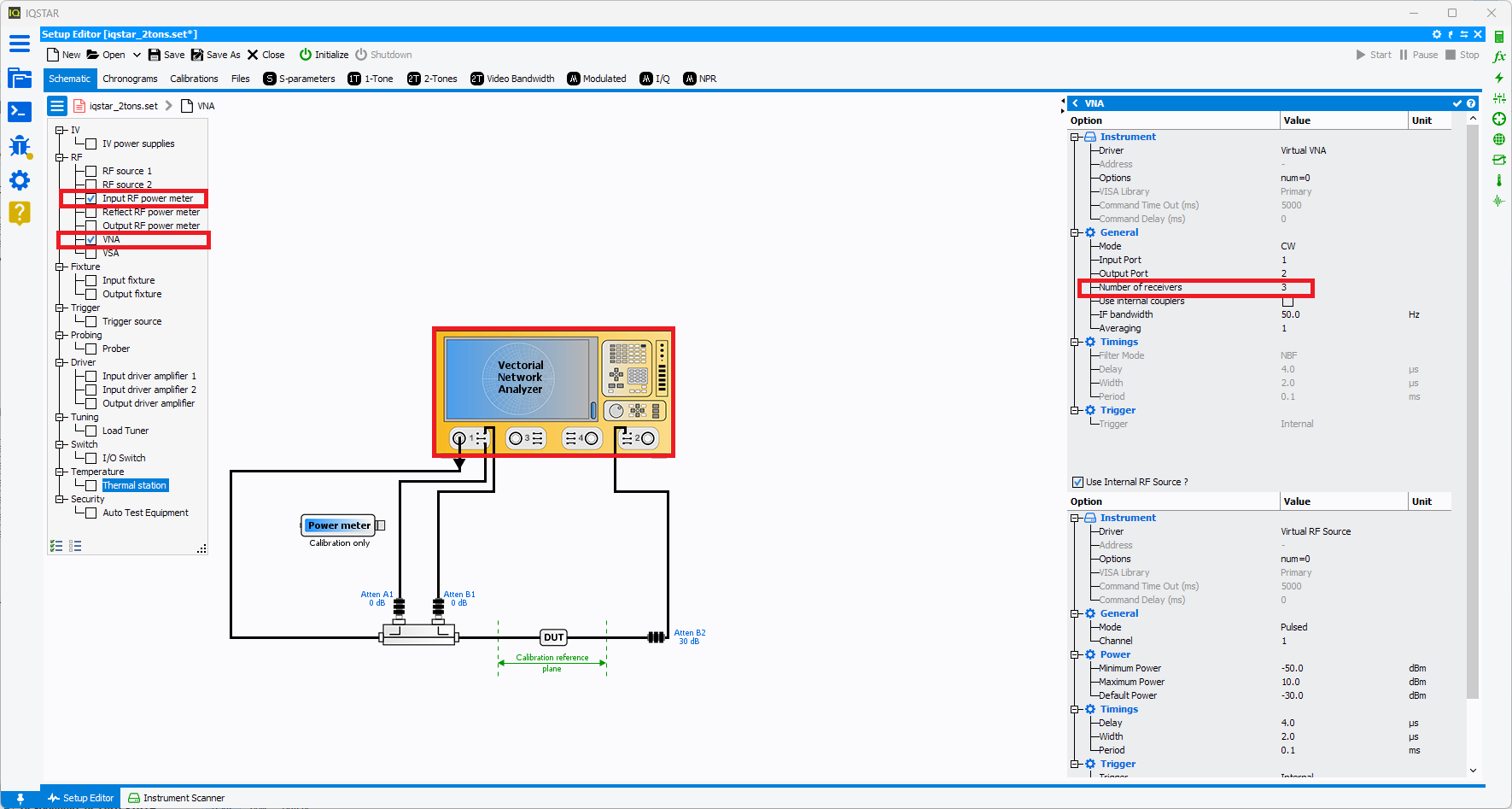

In IQSTAR, the calibration wizard is linked to the Setup Editor configuration. In order to get access to a 1-Port Enhanced calibration wizard, the following conditions have to be respected:

- Vector Network Analyzer and at least one Power Meter need to be enabled

- Number of receiver of Vector Network Analyzer has to be set to 3 or 4

Calibration Wizard

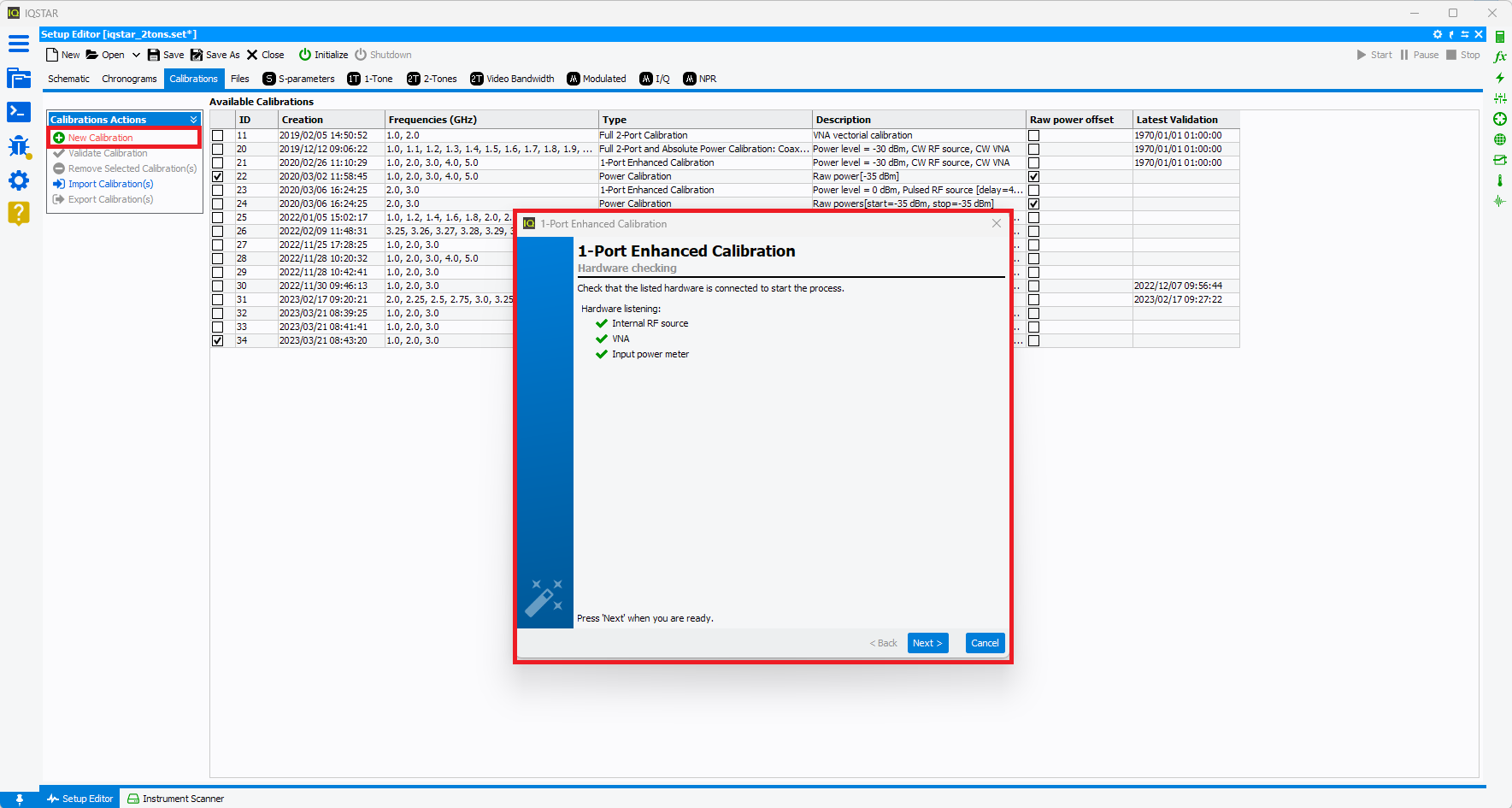

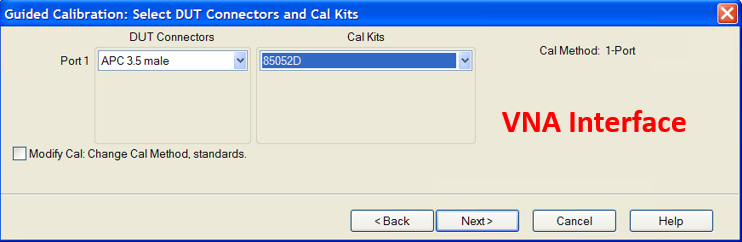

To start a new calibration, select Calibrations tab and click on ‘New Calibration’. The software will verify the communication with each needed instrument and will configure it according to the settings previously defined.

Once all required hardware are listed, click ‘Next’.

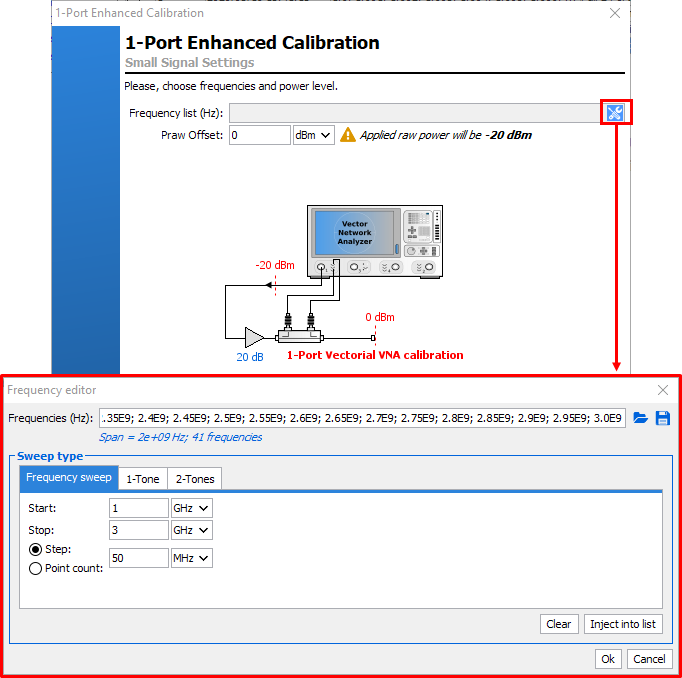

Define the frequency list and the VNA input power level to use during the calibration. The power level should not exceed the maximum power supported by the calibration kit, yet the level should be sufficient to provide noiseless and detectable signals at the VNA receivers even when adding attenuators to keep the receivers safe during the DUT characterization.

In the example above, the sweep type is frequency sweep starting from 1GHz to 3GHz with 50MHz step. In the example below, DUT has 20W output power and 30dB gain amplifier. The calibration will be performed with the RF source of the VNA set to 0dBm at the calibration reference plane. To define the appropriated attenuator values on each receivers, see 2) Power Budget.

Once the frequencies and the VNA power level have been set, click ‘Next’.

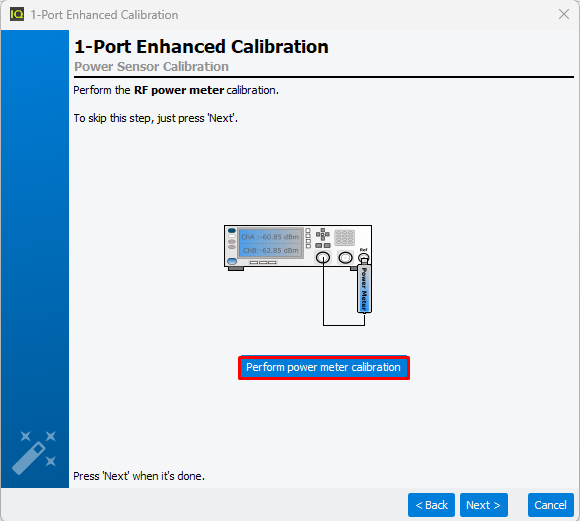

The power sensor can be zeroed and calibrated, if needed, before calibrating the absolute power.

If not, skip this step by clicking ‘Next’.

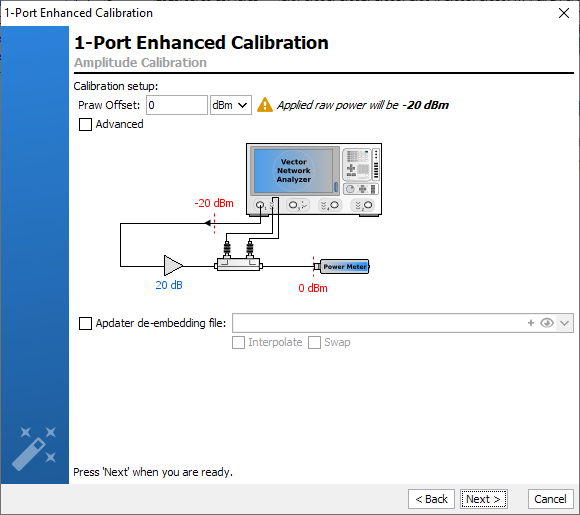

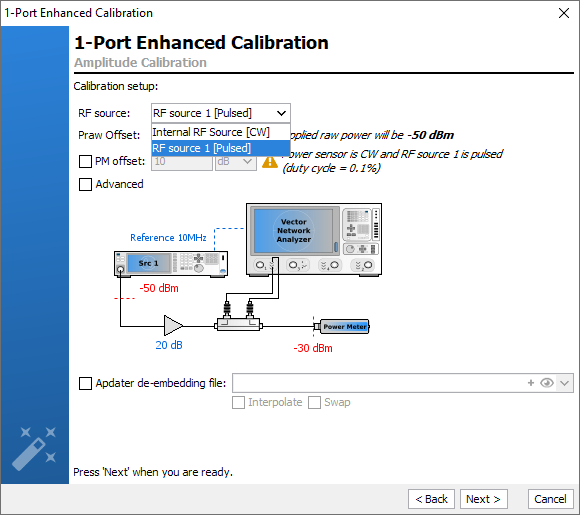

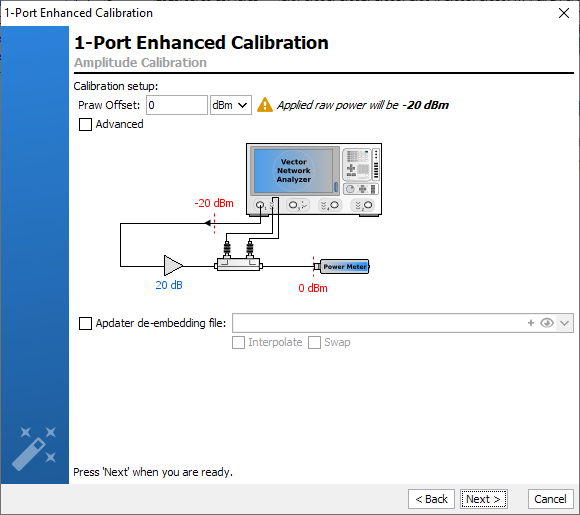

Define the power level used for the absolute power calibration step.

- Basic mode (“No power optimization done”)

In this case, the absolute power error term will be determined on a single power level for each frequency. This calibration method is used when the components of the bench (coupler, attenuator, …) are well-known and already sized to achieve the measurements in the linear range of the receivers.

Set the power level at which you desire to calibrate the receivers. The power meter measurements are compared with the receiver measurements in order to determine the absolute power error term coefficient. Using this error term, the absolute power of the RAW data measured by the receiver is corrected. There are several reasons for which you might change these settings:

- The used power sensor may have power limitations (typically +20 dBm). However, best accuracy is often close to 0 dBm

- If an external component is used in the measurement path, you

MUST adjust this RF source power setting to compensate for these

components. For example, if you want 0 dBm at the calibration

plane and you have a 30dB driver amplifier in the path, you will

need to set -30 dBm for this calibration

For high power amplifiers, attenuators must be placed between receivers and couplers. The more the DUT is powerful the bigger the attenuation needs to be. However, this has a limitation during the calibration process as we need to make sure that the power set for the calibration is well above the noise floor of the receivers on one hand and can be handled by the power sensor on the other hand. In order to avoid damaging to the power sensor and yet increase the accuracy of the calibration, one can add an attenuator to protect the power sensor and use the Adapter de-embedding file to take it into account during power error term calculation.

Note: If a Driver Amplifier is set in the Schematic, the set power level will take into account the Driver Amplifier offset.

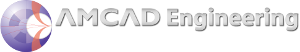

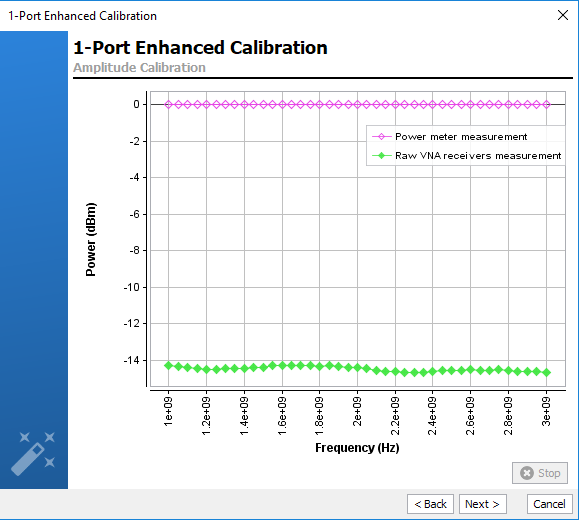

Note: In the example above, the power meter reading is not constant over frequency. This is due to the dispersive behavior of each passive component (couplers, attenuators, driver amplifier, …). In some configurations, this dispersive behavior can lead the power meter to change its measurement range adding uncertainties to the calibration process. In this case, the advanced mode is advised. - Advanced mode (“Power optimization done”)

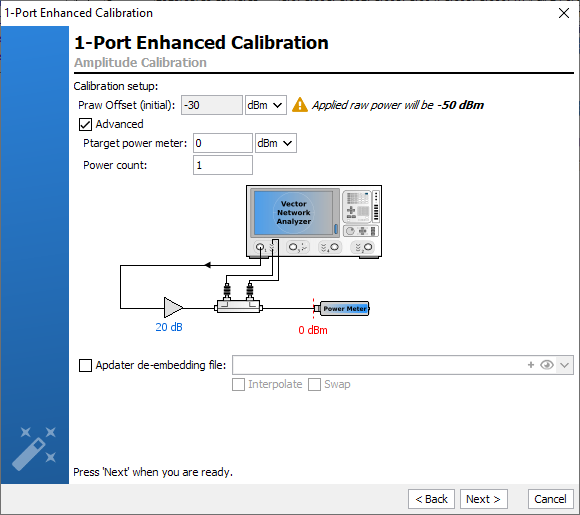

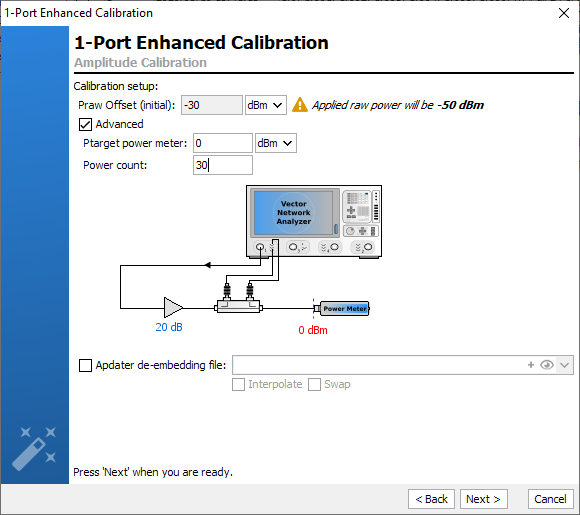

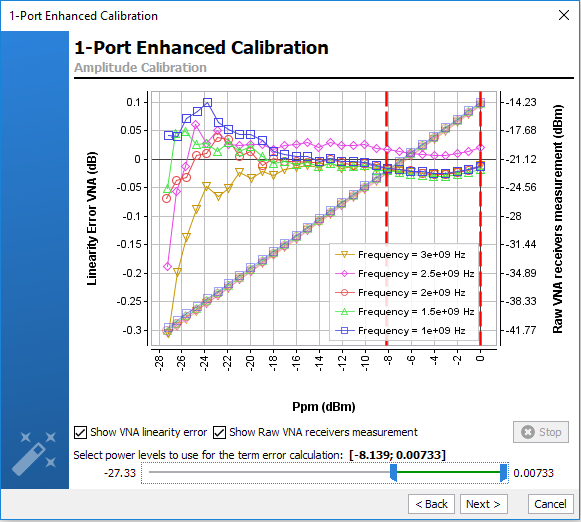

In this case, the absolute power error term will be determined on a power range or on one optimized power level for each frequency. This method is longer than in the basic mode, but it will give also an estimation of the linearity range of the receiver. This calibration method is basically used when the test set bench (coupler, attenuator, …) is not well-known. Therefore, the receiver’s linearity range needs to be checked to evaluate the calibration accuracy.

During this process, the power level of the RF source will be optimized to reach a target value (Ptarget power meter) measured on the power sensor (at the input calibration plane). Then a power sweep will be done from Ptarget power sensor to [Ptarget power sensor– (1dB x Power Count)] in the calibration plane

- Ptarget Power Meter: corresponds to the maximum power level which has to be measured by the power sensor during the power sweep. Note that this level can’t exceed the power sensor limit

- Power count: corresponds to the number of point

of the power sweep. Note that the sweep step is set to 1dB Note: If the Power Count is set to 1, the optimization will be done only at one power level for each frequency.

- Praw Offset (initial) is the initial power

level used during the first iteration of the optimization algorithm.

Note that this power level is linked to the 'Minimum

Power' level set in the RF Source settings. There is a reason that you might change these settings:

- The power sensor that is used may have power limitations (typically +20 dBm). Therefore, the first power level used during the first iteration of the optimization process has to be lower than this limitation to avoid any damages.

For high power amplifiers, attenuators must be placed between receivers and couplers. The more the DUT is powerful the bigger the attenuation needs to be. However, this has a limitation during the calibration process as we need to make sure that the power set for the calibration is well above the noise floor of the receivers on one hand and can be handled by the power sensor on the other hand. In order to avoid damaging to the power sensor and yet increase the accuracy of the calibration, one can add an attenuator to protect the power sensor and use the Adapter de-embedding file to take it into account during power error term calculation.

Contrary to the 'Basic' mode, the power level measured by the power meter remains constant over the frequency range, avoiding the change of measurement range of the power meter.

In this example, the Ptarget power meter value is set to 0dBm, the algorithm applies a power level of Praw Offset (initial) (-30dBm) as a first iteration . During this first iteration, the power sensor returns a value of -34 dBm. In a second step, RF power source level will be adjusted (+4dBm corresponding to -30dBm+34dBm) to reach 0dBm on the power meter. Finally, a power sweep between Ptarget power meter (0dBm) and (Ptarget power meter– 1dB x Power Count) (-30dBm) will be done at each frequency in the calibration plane.

During the calibration process, the RF source level will increase until the power sensor reads the Ptarget power level expected. The process is repeated for each frequency defined in the frequency list (starting from the highest frequency).

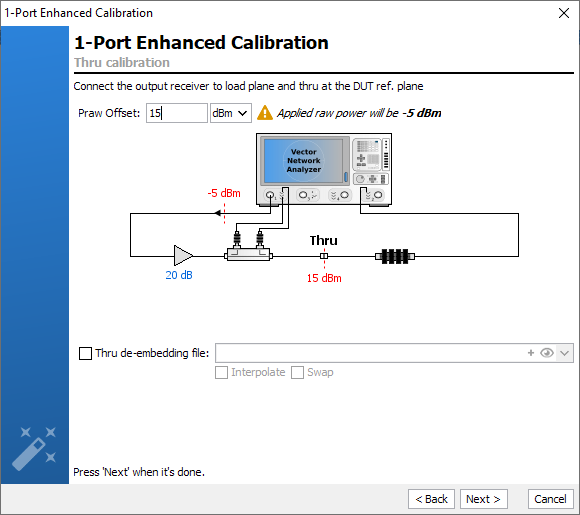

Connect input and output plane using 'Thru' in order to calibrate the output VNA receiver. Set the calibration power level. An appropriate power level for the receiver calibration is the key of an accurate calibration. Depending on the output power of the DUT, the added external output attenuator can have a really high value (>60dB). In this case, the power level used during this calibration should be sufficiently high to provide noiseless and detectable signals to the output receiver.

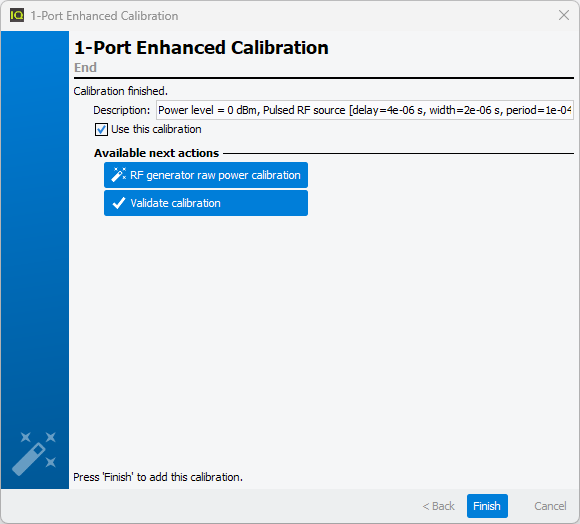

Once the calibration is completed, the error terms are downloaded and recorded in the Calibrations tab. A comment is automatically added but could be modified. This calibration will be used by default for the measurement unless the box Use this calibration is unchecked.

It’s also possible to continue the calibration process by doing a ‘Raw Power Calibration’.

Quick checks can be performed to verify the accuracy of this calibration using Validate calibration button. To learn more see Validate Calibration.