What are the Power Amplifier characterization challenges?

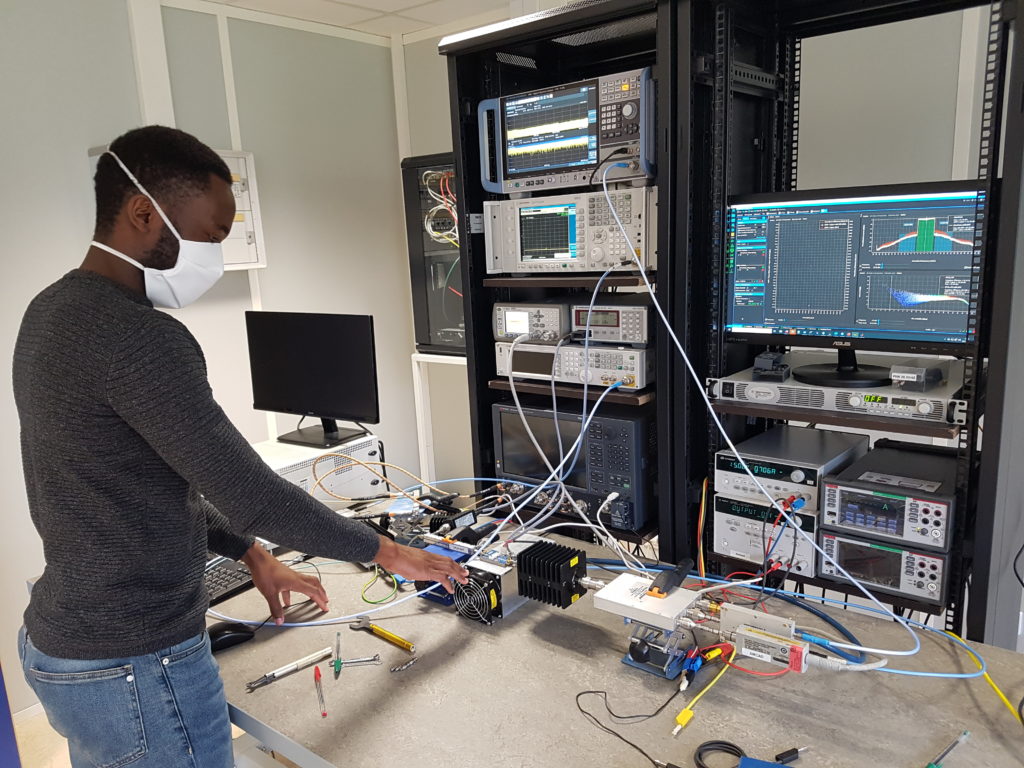

Power Amplifier measurement benches are often equipped with RF instruments from different vendors. Application and test engineers face big challenges when correlating the measurement results with those of their colleagues because equipment models vary from bench to bench and site to site. The testing methodology and data post-processing is usually reviewed to identify the sources of the discrepancies leading to a non-negligible downtime in the qualification process.

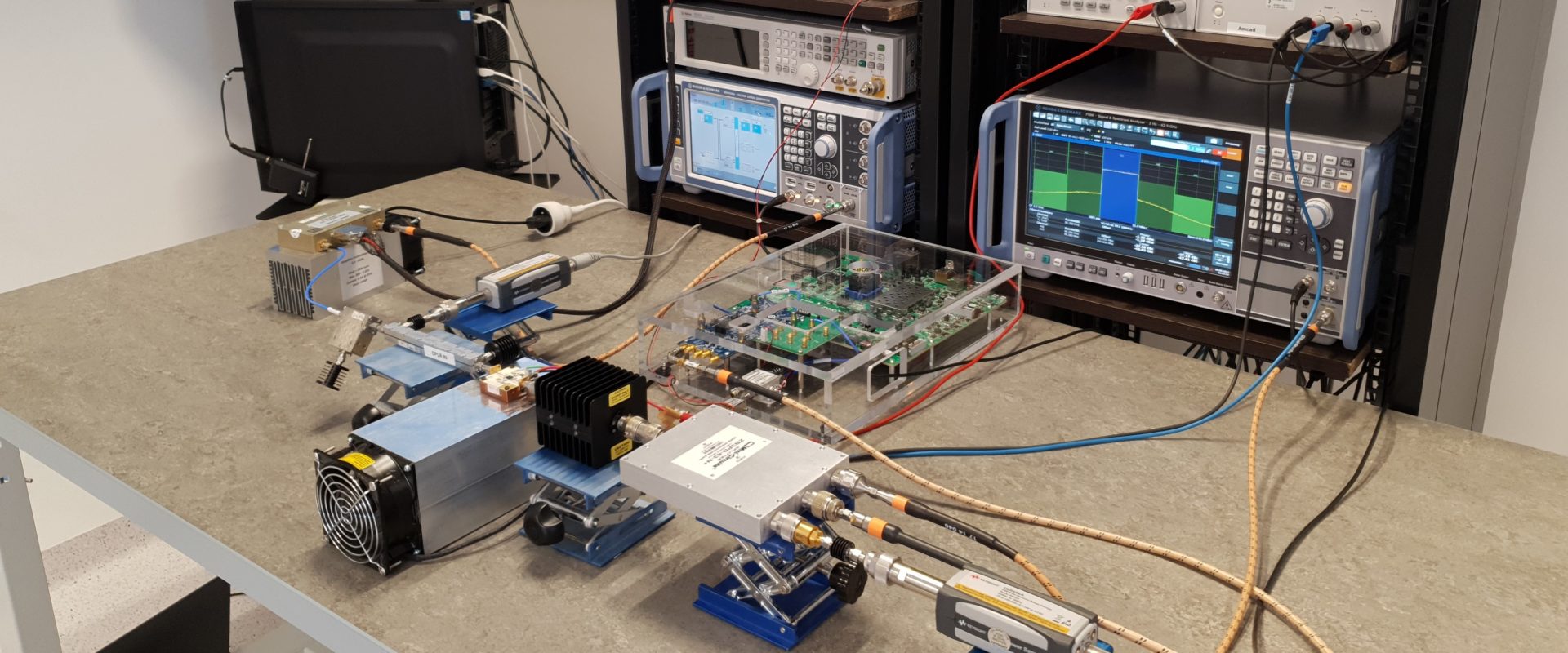

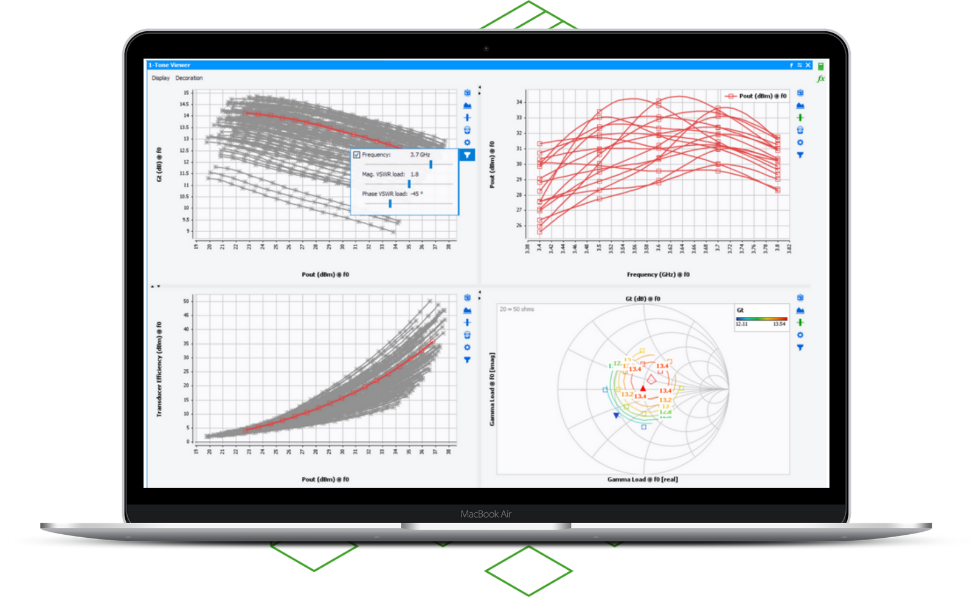

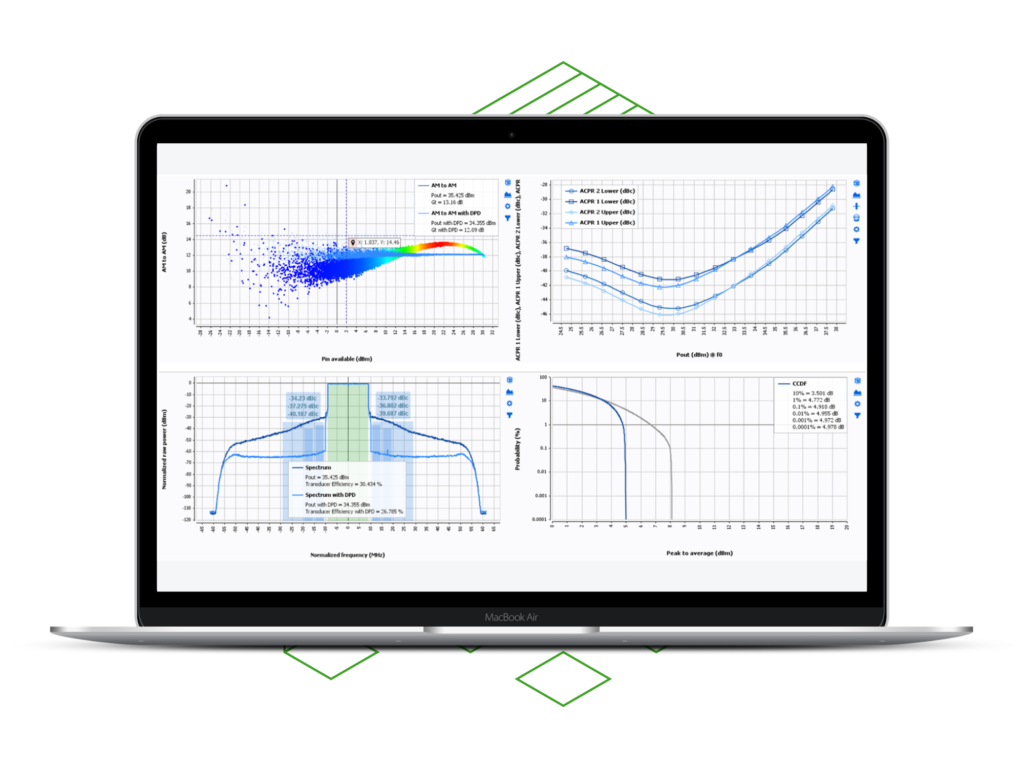

The qualification of power amplifiers requires testing different input signal types and conditions: 1-Tone vs 2-Tone and Continuous Wave vs Pulsed. Each input requires a set of measurements that characterizes the behavior of the PA. Therefore, it is common to see test engineers use dedicated benches for specific measurements, sometimes needing up to 3 benches to cover the complete characterization process. This methodology increases the measurement time considerably and duplicates instruments between the benches, leading to poor CAPEX investment efficiency.

Measurements discrepancy are not only a result of instruments and setup differences. It also comes from the automation software versions that differ from bench to bench and site to site. Indeed, the support of such software is rarely done at a company level but rather follows a specific need (new instrument drivers, new measurements, new setup). Therefore, the releases are not qualified over the entire instrument list of the company, leading to a lack of measurement coherence between the benches. Such cases also impact the team’s efficiency, as some measurements are sometimes done manually for the lack of appropriate internal solution.

IQSTAR is a 50-Ohm circuit characterization software. It was developed after analyzing customers’ and partners’ challenges and request lists. The most important characteristic of the software is the agnostic control of the instruments. Indeed, the software supports multiple instruments from different vendors. Our solution is unique because it integrates over a thousand instrument drivers. Moreover, the setup configuration allows one connection for all the measurements, reducing the downtime and the CAPEX investment. Finally, a dedicated team of RF and Software engineer updates and enhances the software’s capabilities, providing test engineers with a state-of-the-art solution for all their characterization work.